First the video showing off what all this is about

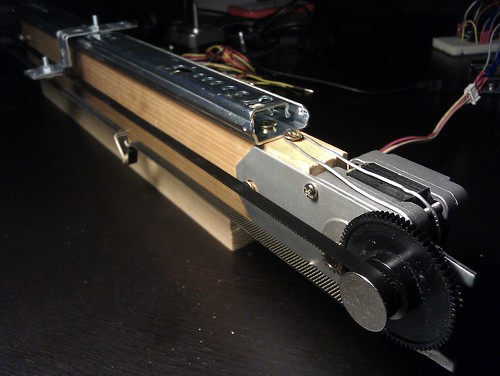

Below you can find a pic of one end of the actuator:

As you can see, I attached the stepper to the piece of wood by just using a wire, and it works great!

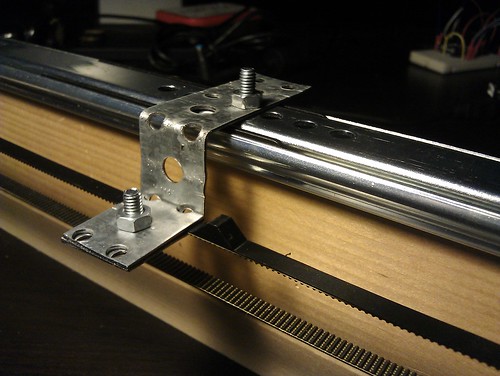

Also note that zigzag piece of metal that links the timing belt with the drawer rail. In the picture below you can see it in more detail

The timing belt is sandwiched between two pieces of metal.

And finally below you can see the pulley at the other end, this was a tricky part, keep reading more the details!

This pulley had an axis that was riveted to the chassis of the scanner, I pulled it off with my pliers and welded it into a screw using solder, I had to heat both parts for a long time before in order to get the solder to bind both parts, the picture below shows the results:

And voila, its working better than I expected! Keep tuned for more and thanks for reading!

BTW greetings goes to the guys in timelab for inspiring me!

Nice build, neat and cheap, but, what can I actually do with it? I'm sorry, I'm older than dirt and slow sometimes.

ReplyDeleteMight make quite a good rig for moving the camera while doing time-lapse photography.

ReplyDeleteWell..It is quite informative post. Thanks for sharing. It was really helpful for me and all credits goes to you only. Cheers man !

ReplyDeletebusiness card scanner

Hello. My name is Dr. Atomic. I've been experimenting for about 45 years. In the process I've experienced the bane of the experimenter. Too much stuff. I have over 450,000 components taking up a huge amount of space. Years ago I started a Yahoo group with the goal of giving it away for free or almost free. Microcontrollers, lasers, optics and parts of all kinds. More than any sane mad scientist can use in a lifetime. How?? I live near Mendelson's Surplus in Dayton, Ohio and having been buying 1000 of something for the cost of 10 for decades. So I'm finding good people who can use this stuff. I guess you could say I'm old school and like to bend tin. However there are people out there who are doing some amazing stuff that I can learn from. So I'm making what I have available to people who will actually use it and in some cases help me use it for my own projects. No matter how good you think you are there's always someone better and more knowledgeable. The goal is to learn and grow. I use SMD/SMT components sometimes because I have steady hands and patience. But sometimes fall down on the coding / software part. When I found your blog I thought to myself that here was someone making the best use of limited resources I've seen in a while. And maybe I could learn something from them. I have things like microcontrollers, lcd displays, high voltage parts (I like Tesla Coils) over 100,000 smt/smd LED chips, tubes, active and passive chips of all kinds and a vast array of components of all kinds from the 1930's to today including the 20th transistor ever made. I found your blog on Hack-a-Day when I was looking for things to do with mouse cameras. So I thought I'd offer what I can in the way of misc. components you might need in exchange for picking your brain from time to time when I get stuck. I started a Yahoo group called The Young Scientists Club with the goal of giving away parts to people Young and Old for free to help them build projects. The problem has been that almost everyone who joined was from India and I found it prohibitive to ship components there for free for very long. So the group stalled. And I'm going the local route and providing components to people like you who do some amazing things with limited resources that I can learn from. I was a physicist for the USAF for a while and found developing weapons didn't fit with my mostly passive nature. So I went into engineering for a radar detector company and honed my skills there. Anyway, now I'm into microcontrollers and robotics (along with optics & of course physics) and am just starting a new learning curve. From reading your blog I see you do interesting stuff and think you could use some of the stuff I have. If you're interested please contact me at HeinrichAtomic@alternativetech.net. I saw the blog on 27256 eproms and having hundreds of them sitting around thought I'd contact you. I thought I was the only one still playing with them and risking my ass using a UV eraser (ha ha). I've since moved onto flash stuff but it caught my attention. Most of what I do is in assembler and I need to move up to higher level languages. Years ago before the availability of cheap CCD/CMOS video sensors I used to use 27C256's as cameras by mapping the bits and displaying them on a monochrome screen. I even used old 64K ram chips from MOSTEK with the lids removed to do the same thing. Now I see some of the amazing things people around me are doing and I'm chomping at the bit to get back into the game. If you're interested or have friends who could use component support, drop me a line. The last thing I built of any significance was a 100 x 100 rgb display using SMT RGB led's and I'm finding most of what I want to work on now can be done by buying modules and making them do things they weren't designed for. Thank you Hack-a-Day. And just if you're curious about why I was looking at mouse cameras I posted on Hack-a-Day under your post. I guess old habits die hard. Thanks for reading.

ReplyDeleteThe DIY laser projector was interesting since I have all of these stepper motor mirror units from old barcode scanners I was looking to do something with.

ReplyDeletehttp://www.publishthesis.com/solution-manuals/

ReplyDeleteExcellent article. Very interesting to read. I really love to read such a nice article. Thanks! keep rocking. wide format laser printer

ReplyDeleteAll linear stepper motors are from this site:oyostepper.com

ReplyDelete